Internship Blog – Day 3: Laser Machine in Denim Washing

Today at Ha-Meem Group, Tongi, I spent my day in the Laser Machine section of the denim washing unit. This section fascinated me the most so far, because it combines technology, creativity, and precision in one process. Unlike manual dry processes such as sandblasting or hand scraping, the laser machine provides a non-contact, eco-friendly, and highly accurate way to create fashionable effects on denim.

🔍 What is a Laser Machine in Denim Washing?

A laser machine is a computer-controlled device that uses a high-intensity laser beam to remove the indigo or dye from the fabric surface in a controlled manner. Instead of physical abrasion, the beam vaporizes the dye and creates the desired patterns, shades, and worn-out looks. This process is widely used in modern denim production for sustainability and efficiency.

⚙️ Key Processes Done by Laser Machine:

- Whisker Effect (Creases/Fades on Thigh Area)

Traditionally done by hand scraping, now whiskers can be designed digitally and applied with a laser machine.

Provides consistency, accuracy, and repeatability without depending on manual skill.

- Chevrons / Honeycombs

Laser creates sharp faded lines at the back of the knees, simulating natural wear-and-tear.

Saves huge manual effort and time.

- Overall Fading

Controlled fading effects over a large garment area.

Looks natural and uniform.

- Destroy/Break Effect

Instead of cutting or grinding manually, laser can burn out specific points to give destroyed looks.

Later washing softens the burnt edge to make it fashionably distressed.

- PP Replacement

Many factories use potassium permanganate spray for localized fading.

Laser is now replacing PP spray in many cases, as it is more eco-friendly and safer for workers.

- 3D and Engraving Designs

With laser technology, logos, texts, and artistic designs can be engraved directly on denim.

This opens huge opportunities for fashion creativity.

🌍 Advantages of Laser Technology:

✅ Eco-friendly – reduces the use of chemicals like PP spray and minimizes water usage.

✅ Consistency – every garment looks the same with uniform effects.

✅ Productivity – much faster than manual hand scraping or grinding.

✅ Worker Safety – eliminates dust and chemical exposure.

✅ Creativity – can make designs that manual processes cannot.

🏭 My Experience Today

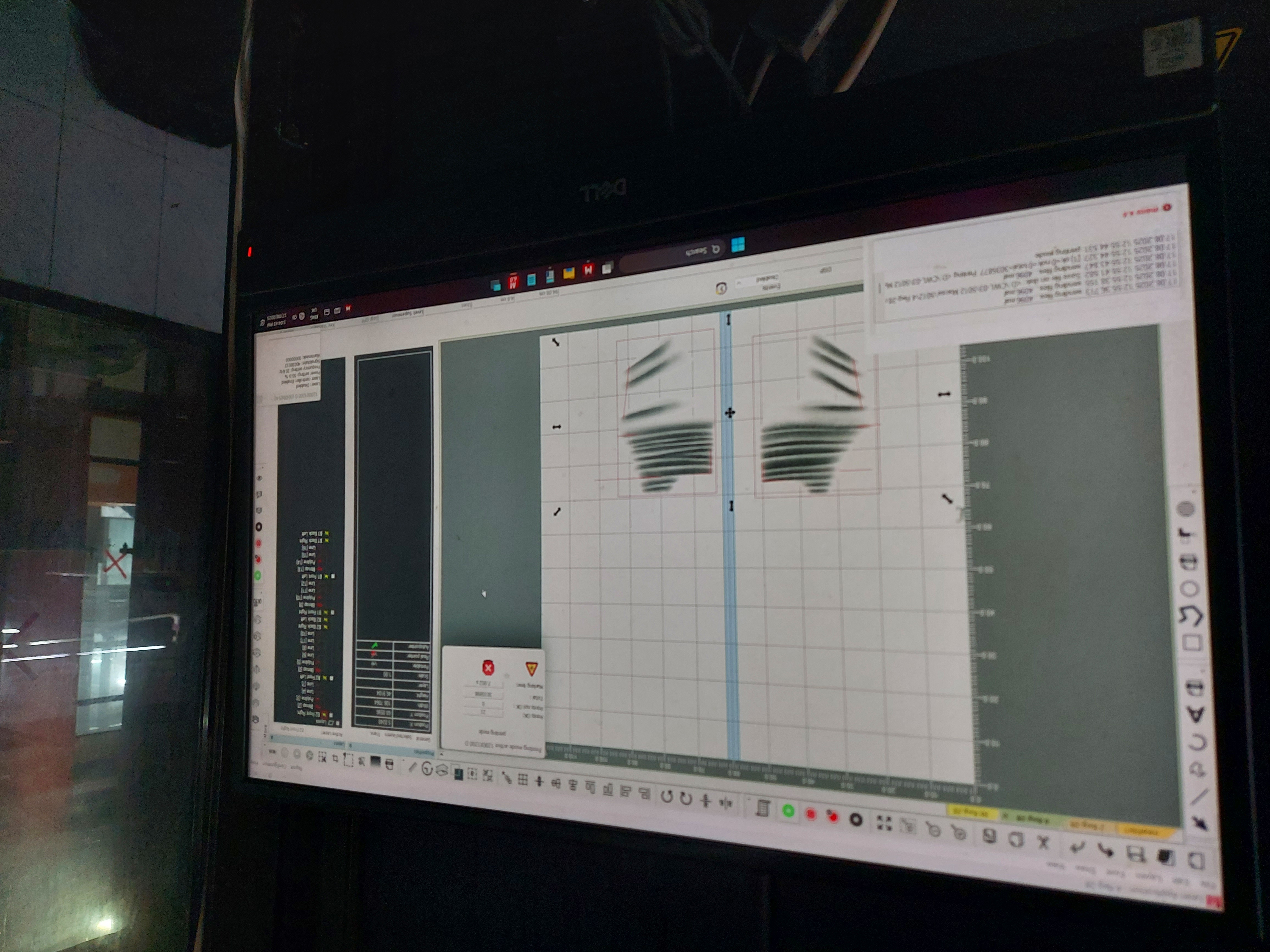

Standing in front of the laser machine, I observed how operators upload a digital design file into the system. With one button, the laser scans across the denim surface and instantly creates fading patterns. The precision was amazing — it looked like art created by technology. I also noticed how the machine can adjust intensity, speed, and DPI (dots per inch) to control the depth and brightness of the fading.

For me, this was one of the most eye-opening parts of my internship because I saw how the garment industry is moving towards automation and sustainability. Laser technology not only saves cost but also helps factories comply with international buyers’ environmental standards.

📊 Internship Learning Flowchart

Here’s the updated flowchart showing our journey through different departments so far:

Washing → Bonded Warehouse (Fabric Inspection, Bonded Warehouse) → Cutting → Sewing (All Cost Calculation, Garments Method) → Finishing & Packing → Merchandising

🔗 Connect With Me

👉 This was my experience from the Laser Machine section today. The combination of technology + fashion + sustainability makes this process one of the most powerful innovations in denim washing.